Taiwan Throttles Up In Auto-Parts Market

Oct 14, 2005 Ι Industry News Ι Auto Parts and Accessories Ι By Quincy, CENS

The recent 2005 Taipei Int'l Auto/Motorcycle Parts & Accessories Show (Taipei AMPA '05) proved once again why this is the biggest and best event of its kind in Asia, serving up cutting-edge products and giving visitors a good picture of where the industry is heading.

The show also underscored Taiwan's success in maintaining its edge in the fierce competition with rivals, particularly South Korea and mainland China, in the aftermarket (AM) auto-parts industry. The key to local players' success against these competitors has been a mixture of low pricing, comprehensive product offerings, rapid product development, and well-developed international sales channels, according to various industry leaders present at the show.

During the event, a number of AM-parts makers also announced ambitious business-expansion projects to meet anticipated growth in demand. Most of the firms in question have evolved from AM-parts makers into original equipment (OE), or tier-one, parts suppliers to many international automakers.

Keyless Entry, Ignition

One example is Tung Thih Enterprise Co., Ltd. (TTE), a leading OE auto-electronics parts supplier to most local automakers. TTE announced that it has won a big-ticket OE order to supply Ford Motor of the United States with reverse sensors for the popular F150 light-truck model starting in 2008.

According to Sarah Chen, vice manager of TTE's marketing and business division, TTE will soon set up a warehouse with on-site engineers near Ford's F150 production plant. She says that the monthly shipment volume for the sensors is expected to outstrip the company's total current shipments to local automakers. "The F150 cooperation project is expected to be TTE's first step in tapping the OE business in the U.S. market, " Chen says. "TTE outgunned Valeo of France to win the supply contract, and we are also in talks with Ford and other American automakers, including General Motors (GM), over supplying parts for other car models."

TTE is already a leading OE supplier of car-alarm, central-lock, power-window, and other auto-electronics systems and parts to several local and mainland Chinese automakers. The company currently operates a plant in Taiwan with 180 workers and another in Xiamen, Fujian Province, mainland China with a workforce of 400.

At Taipei AMPA '05, TTE demonstrated Taiwan's first intelligent keyless-entry device, called "Tech Sense." Tech Sense has remote-sensing capability that enables the locking and unlocking of car doors and trunks. An OE version also adds push-button ignition capability. Tech Sense can also be integrated with a car's original alarm system.

No. 1 Auto-Lamp Exporter

Hu Yuan-lung, sales manager of Depo Auto Parts Ind. Co., Ltd. One of the top-two aftermarket (AM) auto-lamp maker in Taiwan, claims that Depo has outstripped a major rival to become the largest auto-lamp exporter on the island in the first quarter. Hu attributes his company's success to a full-range product-development policy and a well-conceived marketing strategy to establish long-term and stable cooperation ties with distributors worldwide.

"In recent years, Depo has poured NT$600 million to NT$700 million (US$19.1 million to US$22.3 million at US$1:NT$31.4) per year into development of over 300 sets of molds and dies for AM and tuning lamps for Japanese, American, and European car models, " Hu says. "Depo understands that the auto-lamp business depends not only on sales but, more importantly, well-established distribution channels worldwide, long-term and stable cooperation ties with customers, and an ability to adjust production and sales subject to market demand."

Depo supplies auto head, tail, fog, bumper lamps and side markers. Currently, the company supplies over 14, 000 items. Hu claims that his company has maintained a 10% to 20% revenue growth in recent years. "Depo first identifies a target market and then looks for suitable customers in that market, " Hu adds.

Hu says that Depo has not seen a strong growth in demand from Europe, though sales to the region are heading steadily upwards. "For the long term, " Hu claims, "the new Automotive Block Exemption Regulation (BER) 1400/2002/EC in Europe will help Taiwan enter the AM parts market in Europe. The regulation will help qualified local players, such as Depo, compete directly with big rivals that have long dominated the European AM market, like Hella and Bosch. In addition, more and more big international AM-parts brands, especially those in the U.S. and Europe, have been increasing their outsourcing ratios to cut costs. These trends, along with the increasing demand due to the new BER, is expected to help Taiwan AM product makers win more businesses."

Depo demonstrated a series of new AM and tuning auto lamps at the show, including high-end models for Mercedes-Benz limousines and a comprehensive range of popular European car models.

Porsche Tuning Taillights

Though Hu warns that the increasing number of Taiwan auto-lamp makers jumping into the tuning auto-lamp market are expected to hammer prices lower in the near future, IP Import and Export Co., Ltd. (LH) remains optimistic about the future.

LH sales manager Joyce Chang points out that his company has been developing high-end light-emitting diode (LED) tuning taillight market in recent years and currently offers such items in over 40 styles.

"In the highly competitive tuning-lamp market, " says Chang, "LH has found its niche by introducing a series of high-end products, such as tuning taillights for Porsche sport cars and the latest Mercedes-Benz, BMW luxury cars with state-of-the-art optical and styling designs, as well as eyecatching models for popular car models, such as the Peugeot 206 and VW Golf."

The sales of tuning taillights for Porsches and Mercedes are especially lucrative, Chang says, as "the owners of such luxury models usually do not care about how much money they spend to distinguish their vehicles from others." This year, LH rolled out tuning taillights for Porsche Boxster and Mercedes-Benz C-series W202 models.

Pollen Filter

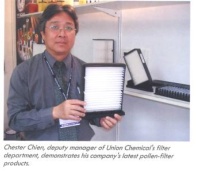

Union Chemical Ind. Co., Ltd. A leading maker of air, fuel, and lubrication filter products for automobiles and machinery and a major local distributor for imported filter materials in Taiwan, says that new environmental protection regulations in Europe have greatly expanded the demand for recyclable filter products. Improved materials and production techniques have also upgraded the quality and filtration ratio of filters.

Chester Chien, deputy manger of Union's filter department, says that his 34-year-old company regularly develops new filter products. Currently, Union supplies filter models for over 1, 000 car models, with two to three new items added per month. One of the company's most recent development focuses has been pollen filters for in-car air filtration. Such filters can filtrate out particles over 0.3 microns in size, including allergens. Union's pollen filters have static-electricity filtration function (which can filtrate 100% of the air in a car cabin within four hours), deodorizing activated carbon, and antibacterial material. In future, Union will develop a negative-ion filter that can purify the air and also enhance health.

Union has also developed one-piece-formed filters made fully of non-woven fabric. The filters, used in engine-intake filtration applications, are compliant with the new material-recycling regulations in Europe. Union produces the filters for both the OE and AM markets.

Chien says his company's core competitiveness lies in combining the functions of manufacturer and material importer. In the latter role, Union is able to access the most advanced materials quickly and at the lowest cost. Union also develops high-end filter products for luxury car models, such as pollen filters for Land Rovers.

Brake Specialist

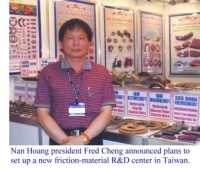

Another company that has prospered in the international market is Nan Hoang Traffic Instrument Co., Ltd. The No. 1 maker of friction materials and products in Taiwan. Fred Cheng, president of the ISO/TS-16949 certified company, says Nan Hoang will move to a new plant in a high-tech industrial zone in southern Taiwan by the end of the year.

Nan Hoang demonstrated the company's latest AA ceramic-fiber brake pads, including models for general cars, amateur racing, and professional racing applications. According to Cheng, the AA series brake pads can withstand at least 500 degrees Celsius (over 700 degrees for the professional racing series); deliver superior braking performance, have long durability, a more stable friction index under different temperature conditions, zero braking noise, and are less prone to deformation under high pressure.

Cheng says that his company's new NT$200 million (US$6.37 million) plant will be three times bigger than the company's current plant. The new facility will also house a friction material R&D center--the only in Asia outside of Japan.

The R&D center will be equipped with NT$60 million (US$1.91 million) in testing and inspection equipment, and all the R&D staff there will have professional certifications in their areas of expertise. The center will also work closely with the labs of leading international companies and research institutes in the area on mutual certification and authorization.

"Nan Hoang's global competitiveness lies in our unmatched development capability, " Cheng claims. "For example, we have developed over 90 non-asbestos friction materials in the past two years and all of them meet the OE supply quality requirements of major automakers. We have positioned our company to play a vital role in upgrading the global status of Taiwan's auto parts industry. To this end we invest heavily and utilize the most advanced equipment to develop over 200 new items per year, including brake linings, shoes and pads as well as clutch plates for automobiles, motorcycles, agricultural machines and other machinery."

Established in 1961, Nan Hoang is the largest and most experienced parts maker in Taiwan. The company now boasts a product lineup of over 4, 000 items, and the figure keeps growing. Last year, Nan Hoang developed Taiwan's first series of full-metal brake shoes and pads, which can withstand temperatures up to 600 degrees. They are made with special materials that deliver a highly stable friction index at high temperatures and under wet working environments. Cheng says that the full-metal friction materials were first applied on aircraft and military armored vehicles and introduced into luxury automobile in recent years.

Ferrari Exhaust

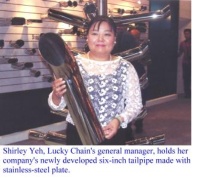

A high-end focus and strong R&D and manufacturing capabilities have helped Lucky Chain Exhaust Co. Ltd. Succeed in the new competitive climate. The company showcased a six-inch-wide truck tailpipe, the largest now made in Taiwan, made with stainless-steel plate.

Shirley Yeh, Lucky Chain's general manager, says that her company's six-inch tailpipes are expected to be very competitive against similar counterparts extruded from 2mm stainless-steel pipes, which are too heavy and too costly.

Lucky Chain developed customized machinery to make the tailpipes with 1.6mm or 1.8mm stainless-steel plate, Yeh says. "The successful mass production of the six-inch tailpipes, " she says, "is consistent with our goals of upgrading production techniques and added significant value to our products."

Lucky Chain was founded in 1986 as a maker of decorative body parts and accessories for trucks. The company began making high-end tuning exhaust products in 1993 for a Japanese customer. The company is now a leading contract supplier of top-end exhaust products to many big international tuning-parts brands in Japan, the U.S., Germany, Italy, France, and other countries.

At Taipei AMPA this year, Lucky Chain exhibited a wide range of top-end tuning exhaust products, including those for Porsche, Ferrari, Mercedes-Benz and BMW models. Yeh says that some exhaust products made by Lucky Chain were demonstrated at Ferrari's automobile-boutique museum. She also says that her company may be the world's largest supplier of Ferrari tuning exhaust systems, as its ships about 500 sets of such product to the automaker each year.

"We pay more attention to detail and quality than our counterparts in the general market, " Yeh says. "Such efforts have earned us strong support from major customers worldwide, many of whom have never once inspected our products before shipment in the past five years."

But success does not come cheap. Lucky Chain pours 15% to 20% of its annual revenue into R&D, including mold/die development, upgrading production processes, and production-equipment upgrading or manufacturing. Yeh claims that her company's revenue surged by 30% last year, and she expects a 50% jump this year. (June 2005)

The show also underscored Taiwan's success in maintaining its edge in the fierce competition with rivals, particularly South Korea and mainland China, in the aftermarket (AM) auto-parts industry. The key to local players' success against these competitors has been a mixture of low pricing, comprehensive product offerings, rapid product development, and well-developed international sales channels, according to various industry leaders present at the show.

During the event, a number of AM-parts makers also announced ambitious business-expansion projects to meet anticipated growth in demand. Most of the firms in question have evolved from AM-parts makers into original equipment (OE), or tier-one, parts suppliers to many international automakers.

Keyless Entry, Ignition

One example is Tung Thih Enterprise Co., Ltd. (TTE), a leading OE auto-electronics parts supplier to most local automakers. TTE announced that it has won a big-ticket OE order to supply Ford Motor of the United States with reverse sensors for the popular F150 light-truck model starting in 2008.

According to Sarah Chen, vice manager of TTE's marketing and business division, TTE will soon set up a warehouse with on-site engineers near Ford's F150 production plant. She says that the monthly shipment volume for the sensors is expected to outstrip the company's total current shipments to local automakers. "The F150 cooperation project is expected to be TTE's first step in tapping the OE business in the U.S. market, " Chen says. "TTE outgunned Valeo of France to win the supply contract, and we are also in talks with Ford and other American automakers, including General Motors (GM), over supplying parts for other car models."

TTE is already a leading OE supplier of car-alarm, central-lock, power-window, and other auto-electronics systems and parts to several local and mainland Chinese automakers. The company currently operates a plant in Taiwan with 180 workers and another in Xiamen, Fujian Province, mainland China with a workforce of 400.

At Taipei AMPA '05, TTE demonstrated Taiwan's first intelligent keyless-entry device, called "Tech Sense." Tech Sense has remote-sensing capability that enables the locking and unlocking of car doors and trunks. An OE version also adds push-button ignition capability. Tech Sense can also be integrated with a car's original alarm system.

No. 1 Auto-Lamp Exporter

Hu Yuan-lung, sales manager of Depo Auto Parts Ind. Co., Ltd. One of the top-two aftermarket (AM) auto-lamp maker in Taiwan, claims that Depo has outstripped a major rival to become the largest auto-lamp exporter on the island in the first quarter. Hu attributes his company's success to a full-range product-development policy and a well-conceived marketing strategy to establish long-term and stable cooperation ties with distributors worldwide.

"In recent years, Depo has poured NT$600 million to NT$700 million (US$19.1 million to US$22.3 million at US$1:NT$31.4) per year into development of over 300 sets of molds and dies for AM and tuning lamps for Japanese, American, and European car models, " Hu says. "Depo understands that the auto-lamp business depends not only on sales but, more importantly, well-established distribution channels worldwide, long-term and stable cooperation ties with customers, and an ability to adjust production and sales subject to market demand."

Depo supplies auto head, tail, fog, bumper lamps and side markers. Currently, the company supplies over 14, 000 items. Hu claims that his company has maintained a 10% to 20% revenue growth in recent years. "Depo first identifies a target market and then looks for suitable customers in that market, " Hu adds.

Hu says that Depo has not seen a strong growth in demand from Europe, though sales to the region are heading steadily upwards. "For the long term, " Hu claims, "the new Automotive Block Exemption Regulation (BER) 1400/2002/EC in Europe will help Taiwan enter the AM parts market in Europe. The regulation will help qualified local players, such as Depo, compete directly with big rivals that have long dominated the European AM market, like Hella and Bosch. In addition, more and more big international AM-parts brands, especially those in the U.S. and Europe, have been increasing their outsourcing ratios to cut costs. These trends, along with the increasing demand due to the new BER, is expected to help Taiwan AM product makers win more businesses."

Depo demonstrated a series of new AM and tuning auto lamps at the show, including high-end models for Mercedes-Benz limousines and a comprehensive range of popular European car models.

Porsche Tuning Taillights

Though Hu warns that the increasing number of Taiwan auto-lamp makers jumping into the tuning auto-lamp market are expected to hammer prices lower in the near future, IP Import and Export Co., Ltd. (LH) remains optimistic about the future.

LH sales manager Joyce Chang points out that his company has been developing high-end light-emitting diode (LED) tuning taillight market in recent years and currently offers such items in over 40 styles.

"In the highly competitive tuning-lamp market, " says Chang, "LH has found its niche by introducing a series of high-end products, such as tuning taillights for Porsche sport cars and the latest Mercedes-Benz, BMW luxury cars with state-of-the-art optical and styling designs, as well as eyecatching models for popular car models, such as the Peugeot 206 and VW Golf."

The sales of tuning taillights for Porsches and Mercedes are especially lucrative, Chang says, as "the owners of such luxury models usually do not care about how much money they spend to distinguish their vehicles from others." This year, LH rolled out tuning taillights for Porsche Boxster and Mercedes-Benz C-series W202 models.

Pollen Filter

Union Chemical Ind. Co., Ltd. A leading maker of air, fuel, and lubrication filter products for automobiles and machinery and a major local distributor for imported filter materials in Taiwan, says that new environmental protection regulations in Europe have greatly expanded the demand for recyclable filter products. Improved materials and production techniques have also upgraded the quality and filtration ratio of filters.

Chester Chien, deputy manger of Union's filter department, says that his 34-year-old company regularly develops new filter products. Currently, Union supplies filter models for over 1, 000 car models, with two to three new items added per month. One of the company's most recent development focuses has been pollen filters for in-car air filtration. Such filters can filtrate out particles over 0.3 microns in size, including allergens. Union's pollen filters have static-electricity filtration function (which can filtrate 100% of the air in a car cabin within four hours), deodorizing activated carbon, and antibacterial material. In future, Union will develop a negative-ion filter that can purify the air and also enhance health.

Union has also developed one-piece-formed filters made fully of non-woven fabric. The filters, used in engine-intake filtration applications, are compliant with the new material-recycling regulations in Europe. Union produces the filters for both the OE and AM markets.

Chien says his company's core competitiveness lies in combining the functions of manufacturer and material importer. In the latter role, Union is able to access the most advanced materials quickly and at the lowest cost. Union also develops high-end filter products for luxury car models, such as pollen filters for Land Rovers.

Brake Specialist

Another company that has prospered in the international market is Nan Hoang Traffic Instrument Co., Ltd. The No. 1 maker of friction materials and products in Taiwan. Fred Cheng, president of the ISO/TS-16949 certified company, says Nan Hoang will move to a new plant in a high-tech industrial zone in southern Taiwan by the end of the year.

Nan Hoang demonstrated the company's latest AA ceramic-fiber brake pads, including models for general cars, amateur racing, and professional racing applications. According to Cheng, the AA series brake pads can withstand at least 500 degrees Celsius (over 700 degrees for the professional racing series); deliver superior braking performance, have long durability, a more stable friction index under different temperature conditions, zero braking noise, and are less prone to deformation under high pressure.

Cheng says that his company's new NT$200 million (US$6.37 million) plant will be three times bigger than the company's current plant. The new facility will also house a friction material R&D center--the only in Asia outside of Japan.

The R&D center will be equipped with NT$60 million (US$1.91 million) in testing and inspection equipment, and all the R&D staff there will have professional certifications in their areas of expertise. The center will also work closely with the labs of leading international companies and research institutes in the area on mutual certification and authorization.

"Nan Hoang's global competitiveness lies in our unmatched development capability, " Cheng claims. "For example, we have developed over 90 non-asbestos friction materials in the past two years and all of them meet the OE supply quality requirements of major automakers. We have positioned our company to play a vital role in upgrading the global status of Taiwan's auto parts industry. To this end we invest heavily and utilize the most advanced equipment to develop over 200 new items per year, including brake linings, shoes and pads as well as clutch plates for automobiles, motorcycles, agricultural machines and other machinery."

Established in 1961, Nan Hoang is the largest and most experienced parts maker in Taiwan. The company now boasts a product lineup of over 4, 000 items, and the figure keeps growing. Last year, Nan Hoang developed Taiwan's first series of full-metal brake shoes and pads, which can withstand temperatures up to 600 degrees. They are made with special materials that deliver a highly stable friction index at high temperatures and under wet working environments. Cheng says that the full-metal friction materials were first applied on aircraft and military armored vehicles and introduced into luxury automobile in recent years.

Ferrari Exhaust

A high-end focus and strong R&D and manufacturing capabilities have helped Lucky Chain Exhaust Co. Ltd. Succeed in the new competitive climate. The company showcased a six-inch-wide truck tailpipe, the largest now made in Taiwan, made with stainless-steel plate.

Shirley Yeh, Lucky Chain's general manager, says that her company's six-inch tailpipes are expected to be very competitive against similar counterparts extruded from 2mm stainless-steel pipes, which are too heavy and too costly.

Lucky Chain developed customized machinery to make the tailpipes with 1.6mm or 1.8mm stainless-steel plate, Yeh says. "The successful mass production of the six-inch tailpipes, " she says, "is consistent with our goals of upgrading production techniques and added significant value to our products."

Lucky Chain was founded in 1986 as a maker of decorative body parts and accessories for trucks. The company began making high-end tuning exhaust products in 1993 for a Japanese customer. The company is now a leading contract supplier of top-end exhaust products to many big international tuning-parts brands in Japan, the U.S., Germany, Italy, France, and other countries.

At Taipei AMPA this year, Lucky Chain exhibited a wide range of top-end tuning exhaust products, including those for Porsche, Ferrari, Mercedes-Benz and BMW models. Yeh says that some exhaust products made by Lucky Chain were demonstrated at Ferrari's automobile-boutique museum. She also says that her company may be the world's largest supplier of Ferrari tuning exhaust systems, as its ships about 500 sets of such product to the automaker each year.

"We pay more attention to detail and quality than our counterparts in the general market, " Yeh says. "Such efforts have earned us strong support from major customers worldwide, many of whom have never once inspected our products before shipment in the past five years."

But success does not come cheap. Lucky Chain pours 15% to 20% of its annual revenue into R&D, including mold/die development, upgrading production processes, and production-equipment upgrading or manufacturing. Yeh claims that her company's revenue surged by 30% last year, and she expects a 50% jump this year. (June 2005)

©1995-2006 Copyright China Economic News Service All Rights Reserved.