Taiwan Cooks Up Innovative Designs

Oct 03, 2005 Ι Industry News Ι Furniture Ι By Ben, CENS

With more than two decades of development, Taiwan's kitchen furniture and accessories sector has made a successful transformation from contract manufacturing to focus on the production of original design manufacturer (ODM) items. The shift has resulted from intensive efforts in the local industry to enhance design ability over the past few years, such that many manufacturers in the sector are now highly adept at designing innovative products to meet the special requirements of customers from around the world.

Many of the innovative products developed by domestic manufacturers in this line feature streamlined designs, convenient operation, and environmentally friendly manufacture.

Despite their recent competitive gains, furniture and accessory makers in Taiwan worry about the skyrocketing prices of iron and steel, which are major raw materials in the production of domestically made kitchen furniture and relevant accessories. They are also keeping a wary eye on price competition from developing nations, especially from neighboring mainland China.

On the issue of rising raw material costs, local producers hope that China Steel Corporation, Taiwan's largest integrated producer of steel products, can lower its price to help furniture makers survive soaring material costs.

With regards to price competition from mainland, some domestic manufacturers have responded by moving their production lines across the Taiwan Strait to tap low production costs there. Others have stayed rooted in Taiwan by upgrading their manufacturing skill to lean toward high-value-added, and multifunctional product lines. This latter group believes that Taiwan has to continually elevate product quality to survive in the international marketplace.

Aiming High

Jia Shen Enterprise Co., Ltd., established in 2004, has been concentrating on high-end furniture products. Despite the exodus of some medium and large producers in this line, the company continues to roll out kitchen hardware in Taiwan and concentrate on high-quality products.

Currently the company assembles a wide rage of kitchen furniture products using iron wire and piping. All of its products feature attractive designs.

Jia Shen has an assembly plant located in Lungching of Taichung County, central Taiwan. Many important manufacturing processes are completed in-house. Although the company entrusts outside specialists to handle coating processes, it strictly inspects all finished products before they are shipped.

The company is capable of manufacturing metal wire products to meet the special requirements of different markets around the world. "Our prowess exists in our strong design capability, " says Liu Chung-chou, president of the company. "We have three highly experienced designers in charge of developing innovative products."

In addition to its self-developed designs, Jia Shen also produces items based on customers' original designs. "In fact, a majority of our products are tailored to meet our customers' designs. Only a small part of our product line is created by our own designers, " says Liu. Liu says that his company plans to shift more emphasis to ODM products in the future.

Liu says his company is also paying close attention to reducing shipment time as global customers demand quicker delivery of products.

At present the company exports all of its products, mainly to the Untied States, South Korea and Western Europe. "I believe my company will be able to develop more export markets in the foreseeable future as our products have been widely accepted in several advanced nations, " says Liu.

To offset the rising cost of raw materials, Liu's company began raising prices on its products at the end of last year. He concedes that it is difficult to pass on its higher production costs to customers in the current competitive environment. "Fortunately the average material price has dropped 20% over the past two months, " he says.

Faced with falling profit margins, Jia Shen has adopted a strict internal control procedure to reduce production costs. Liu expects such moves to pay off its sharply rising order volumes in the year ahead.

Finishing First

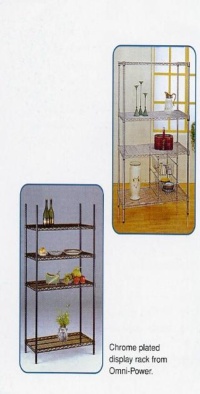

Omni-power Co., established in 1986, specializes in satin chrome and brushed chrome finish methods to complete display racks, store furniture, ship fittings, sign holders, hangers, and display mannequins.

The company owns a 55, 000-square-foot factory in Chiayi County, southern Taiwan, and a 36, 500-square-foot warehouse in Los Angeles, USA. The company established the L.A. warehouse to speed up delivery to customers in North America.

Omni-Power has a strong in-house R&D team that has helped the company expand its product offering to meet the demand of customers from around the world.

In the first half of this year, the company launched several new product series, including lockable garment rack covers made of navy blue nylon. The new product measures 60 inches long and 50 inches wide. Other new items include salesman's bags, acrylic hosiery bins, acrylic brochure holders, diamond wire shelving systems, and small commercial garment racks.

Omi-Power's products are NSF-approved, ensuring the quality of its products. The company says it welcomes cooperation with foreign customers in designing and developing new products that meet international market demand.

Coating King

Uei Shin Industrial Co., Ltd., has more than two decades of manufacturing experience, making it one of Taiwan's oldest makers of metal wire products. The company employs several skilled in-house designers to develop its high-quality products, which include Teflon-coated and enameled barbecue equipment, metal wire kitchen racks, and small kitchen utensils.

The company's plant in the central Taiwan city of Changhua uses sophisticated coating equipment to ensure high quality. Exports account for over 90% of total production.

"We began promoting exports some seven or eight years ago, " says Uei Shin president Kuo Kuo-chin. "We have found that our exports are growing faster than our domestic sales. Our export orientation has pushed us to develop more sophisticated product lines because our foreign customers, especially those from the U.S., Japan, and Europe, want high-end products."

The company's expertise is in the development of multifunction kitchen utensils. Its kitchen racks, for example, can be easily height adjusted and they can be developed as wall-mounted or floor types.

Uei Shin claims it has made big strides in the development of innovative kitchen racks and knock-down barbecue equipment.

Kitchen and Bathroom Décor

Headquartered in the northern Taiwan county of Taipei, Decorway Co. currently concentrates on the design and marketing of innovative iron-wire and metal-related products, mostly for kitchen and bathroom use, and has invested in several joint-venture plants in Taiwan and mainland China.

The company claims that it is capable of developing a wide range of high-quality kitchen and bathroom utensils. Currently, the company's main product lines are wire shelving systems, kitchen and bathroom organizers, display and shop fittings, wire rank and forming products, wire mesh product, and wire-formed decorative lighting.

The company's dedicated in-house R&D team designs sophisticated and high quality products. This capability, plus rapid delivery, has enabled Decorway to establish long-term relations with many of its customers.

Most Decorway products are sold through boutiques in highly industrialized nations such as the United States, the United Kingdom, and Germany.

"We have four talented in-house designers who develop innovative products in accordance with the latest world fashions, " reports Steven Lin, the company's general manager. "It's time for domestic manufacturers to focus on products with new designs instead of those mass-produced items, because our rival manufacturers in mainland China can beat us at mass production."

"All of our products are highly functional, convenient and distinctive. That's the only way we can stand firmly in the international market."

The company's joint-venture plants use stainless steel and low-carbon steel wire to make kitchen and bathroom products. The stainless-steel products can be chrome-plated or electro-polished, while those made of low-carbon steel wire are all chrome-plated. "We are very careful at each stage of the production processes, starting from the selection of raw materials, " Lin says. "For instance, we use top-grade stainless steel to make sure that are products stay rust-free."

Impressive Displays

Matthew Comfort Co., Ltd., one of Taiwan's leading manufacturers of knock-down (K/D) metal display racks, is retooling production equipment and increasing installment of state-of-the-art surface treatment equipment to greatly the enhance quality of its products.

Over the past few years, the company has been using retained earnings to improve its operating environment and enhance production equipment under the leadership of its president Matthew Yang.

"As a medium and small enterprise, we have to concentrate on efficient management and raise our ability to provide rapid responses to our customers' urgent requirements, " Yang says. "That's why we are constantly boosting our efficiency and optimizing our production model."

At Mathew, Yang is in charge of on-spot production and his wife for administrative and financial affairs.

Yang emphasizes the importance of employees to the success of his company and therefore pays special attention to caring for his staff through such perks as a leisure park adjacent to the production facility. To raise worker productivity, Matthew also provides professional and on-the-job training courses. "Such training has helped elevate our corporate image because our long-term customers said they have increased confidence on our products and our ability to ship high-quality products, " Yang states.

Just four years ago, Matthew inaugurated a 216, 000-square-foot new plant in Peitou of Changhua County, central Taiwan to make sophisticated metal racks. The plant is equipped with automated production equipment and large-sized advanced surface-treatment equipment. The company handles front-end processing processes, including metal wire cutting, carbon dioxide spot welding, metal sheet cutting/folding, module setting, and other processes at its older plant.

Although many domestic furniture manufacturers have moved their production facilities to mainland China and Southeast Asian nations over the past few years, the Matthew insists on keeping production in Taiwan. Due to the employment of a strict quality control system and long-term innovation efforts, the company claims it has several production advantages over its counterparts.

The ISO-9001-certified manufacturer adopts modern management concepts at the new plant, which is equipped with advanced automated coating equipment and a three-story automated storage and retrieval system (AS/RS). "The advanced AS/RS mechanism has helped us cut processing times and save space because it can smartly locate raw materials as well as store finished products, " notes Yang.

A professional manufacturer of metal racks used in kitchen and bedroom, Matthew is capable of farming out extensive lines of functional K/D home office furniture. The company offers its products in a variety of styles and finishes.

At present, the company's product lines include general-purpose racks, computer desks with book stands, computer racks, coat racks, kitchenware racks, wine racks, bookshelves, multi-purpose carts, magazine holders, trash cans, umbrella holders, medical carts, and compact disk racks. All the products made by the company comply with the U.S.'s NSF quality standard.

Since its establishment, Matthew has increased the use of various kinds of raw materials to facilitate production of multifunctional products. In the early stage, the company adopted only iron wire to produce metal racks. Today it also uses iron plate, iron pipe, aluminum alloy, stainless steel, plastics, glass and wood.

So far the company has acquired many patents in the United States, Japan, United Kingdom, Germany, France, Taiwan, and mainland China.

"We export all of our products, mostly on an OEM basis, " says Yang. "Japan is our largest outlet by taking up 60% of our total sales, followed by Europe with 35% and the U.S. 5%. This market mix underscores the reliability of our quality."

Many of the innovative products developed by domestic manufacturers in this line feature streamlined designs, convenient operation, and environmentally friendly manufacture.

Despite their recent competitive gains, furniture and accessory makers in Taiwan worry about the skyrocketing prices of iron and steel, which are major raw materials in the production of domestically made kitchen furniture and relevant accessories. They are also keeping a wary eye on price competition from developing nations, especially from neighboring mainland China.

On the issue of rising raw material costs, local producers hope that China Steel Corporation, Taiwan's largest integrated producer of steel products, can lower its price to help furniture makers survive soaring material costs.

With regards to price competition from mainland, some domestic manufacturers have responded by moving their production lines across the Taiwan Strait to tap low production costs there. Others have stayed rooted in Taiwan by upgrading their manufacturing skill to lean toward high-value-added, and multifunctional product lines. This latter group believes that Taiwan has to continually elevate product quality to survive in the international marketplace.

Aiming High

Jia Shen Enterprise Co., Ltd., established in 2004, has been concentrating on high-end furniture products. Despite the exodus of some medium and large producers in this line, the company continues to roll out kitchen hardware in Taiwan and concentrate on high-quality products.

Currently the company assembles a wide rage of kitchen furniture products using iron wire and piping. All of its products feature attractive designs.

Jia Shen has an assembly plant located in Lungching of Taichung County, central Taiwan. Many important manufacturing processes are completed in-house. Although the company entrusts outside specialists to handle coating processes, it strictly inspects all finished products before they are shipped.

The company is capable of manufacturing metal wire products to meet the special requirements of different markets around the world. "Our prowess exists in our strong design capability, " says Liu Chung-chou, president of the company. "We have three highly experienced designers in charge of developing innovative products."

In addition to its self-developed designs, Jia Shen also produces items based on customers' original designs. "In fact, a majority of our products are tailored to meet our customers' designs. Only a small part of our product line is created by our own designers, " says Liu. Liu says that his company plans to shift more emphasis to ODM products in the future.

Liu says his company is also paying close attention to reducing shipment time as global customers demand quicker delivery of products.

At present the company exports all of its products, mainly to the Untied States, South Korea and Western Europe. "I believe my company will be able to develop more export markets in the foreseeable future as our products have been widely accepted in several advanced nations, " says Liu.

To offset the rising cost of raw materials, Liu's company began raising prices on its products at the end of last year. He concedes that it is difficult to pass on its higher production costs to customers in the current competitive environment. "Fortunately the average material price has dropped 20% over the past two months, " he says.

Faced with falling profit margins, Jia Shen has adopted a strict internal control procedure to reduce production costs. Liu expects such moves to pay off its sharply rising order volumes in the year ahead.

Finishing First

Omni-power Co., established in 1986, specializes in satin chrome and brushed chrome finish methods to complete display racks, store furniture, ship fittings, sign holders, hangers, and display mannequins.

The company owns a 55, 000-square-foot factory in Chiayi County, southern Taiwan, and a 36, 500-square-foot warehouse in Los Angeles, USA. The company established the L.A. warehouse to speed up delivery to customers in North America.

Omni-Power has a strong in-house R&D team that has helped the company expand its product offering to meet the demand of customers from around the world.

In the first half of this year, the company launched several new product series, including lockable garment rack covers made of navy blue nylon. The new product measures 60 inches long and 50 inches wide. Other new items include salesman's bags, acrylic hosiery bins, acrylic brochure holders, diamond wire shelving systems, and small commercial garment racks.

Omi-Power's products are NSF-approved, ensuring the quality of its products. The company says it welcomes cooperation with foreign customers in designing and developing new products that meet international market demand.

Coating King

Uei Shin Industrial Co., Ltd., has more than two decades of manufacturing experience, making it one of Taiwan's oldest makers of metal wire products. The company employs several skilled in-house designers to develop its high-quality products, which include Teflon-coated and enameled barbecue equipment, metal wire kitchen racks, and small kitchen utensils.

The company's plant in the central Taiwan city of Changhua uses sophisticated coating equipment to ensure high quality. Exports account for over 90% of total production.

"We began promoting exports some seven or eight years ago, " says Uei Shin president Kuo Kuo-chin. "We have found that our exports are growing faster than our domestic sales. Our export orientation has pushed us to develop more sophisticated product lines because our foreign customers, especially those from the U.S., Japan, and Europe, want high-end products."

The company's expertise is in the development of multifunction kitchen utensils. Its kitchen racks, for example, can be easily height adjusted and they can be developed as wall-mounted or floor types.

Uei Shin claims it has made big strides in the development of innovative kitchen racks and knock-down barbecue equipment.

Kitchen and Bathroom Décor

Headquartered in the northern Taiwan county of Taipei, Decorway Co. currently concentrates on the design and marketing of innovative iron-wire and metal-related products, mostly for kitchen and bathroom use, and has invested in several joint-venture plants in Taiwan and mainland China.

The company claims that it is capable of developing a wide range of high-quality kitchen and bathroom utensils. Currently, the company's main product lines are wire shelving systems, kitchen and bathroom organizers, display and shop fittings, wire rank and forming products, wire mesh product, and wire-formed decorative lighting.

The company's dedicated in-house R&D team designs sophisticated and high quality products. This capability, plus rapid delivery, has enabled Decorway to establish long-term relations with many of its customers.

Most Decorway products are sold through boutiques in highly industrialized nations such as the United States, the United Kingdom, and Germany.

"We have four talented in-house designers who develop innovative products in accordance with the latest world fashions, " reports Steven Lin, the company's general manager. "It's time for domestic manufacturers to focus on products with new designs instead of those mass-produced items, because our rival manufacturers in mainland China can beat us at mass production."

"All of our products are highly functional, convenient and distinctive. That's the only way we can stand firmly in the international market."

The company's joint-venture plants use stainless steel and low-carbon steel wire to make kitchen and bathroom products. The stainless-steel products can be chrome-plated or electro-polished, while those made of low-carbon steel wire are all chrome-plated. "We are very careful at each stage of the production processes, starting from the selection of raw materials, " Lin says. "For instance, we use top-grade stainless steel to make sure that are products stay rust-free."

Impressive Displays

Matthew Comfort Co., Ltd., one of Taiwan's leading manufacturers of knock-down (K/D) metal display racks, is retooling production equipment and increasing installment of state-of-the-art surface treatment equipment to greatly the enhance quality of its products.

Over the past few years, the company has been using retained earnings to improve its operating environment and enhance production equipment under the leadership of its president Matthew Yang.

"As a medium and small enterprise, we have to concentrate on efficient management and raise our ability to provide rapid responses to our customers' urgent requirements, " Yang says. "That's why we are constantly boosting our efficiency and optimizing our production model."

At Mathew, Yang is in charge of on-spot production and his wife for administrative and financial affairs.

Yang emphasizes the importance of employees to the success of his company and therefore pays special attention to caring for his staff through such perks as a leisure park adjacent to the production facility. To raise worker productivity, Matthew also provides professional and on-the-job training courses. "Such training has helped elevate our corporate image because our long-term customers said they have increased confidence on our products and our ability to ship high-quality products, " Yang states.

Just four years ago, Matthew inaugurated a 216, 000-square-foot new plant in Peitou of Changhua County, central Taiwan to make sophisticated metal racks. The plant is equipped with automated production equipment and large-sized advanced surface-treatment equipment. The company handles front-end processing processes, including metal wire cutting, carbon dioxide spot welding, metal sheet cutting/folding, module setting, and other processes at its older plant.

Although many domestic furniture manufacturers have moved their production facilities to mainland China and Southeast Asian nations over the past few years, the Matthew insists on keeping production in Taiwan. Due to the employment of a strict quality control system and long-term innovation efforts, the company claims it has several production advantages over its counterparts.

The ISO-9001-certified manufacturer adopts modern management concepts at the new plant, which is equipped with advanced automated coating equipment and a three-story automated storage and retrieval system (AS/RS). "The advanced AS/RS mechanism has helped us cut processing times and save space because it can smartly locate raw materials as well as store finished products, " notes Yang.

A professional manufacturer of metal racks used in kitchen and bedroom, Matthew is capable of farming out extensive lines of functional K/D home office furniture. The company offers its products in a variety of styles and finishes.

At present, the company's product lines include general-purpose racks, computer desks with book stands, computer racks, coat racks, kitchenware racks, wine racks, bookshelves, multi-purpose carts, magazine holders, trash cans, umbrella holders, medical carts, and compact disk racks. All the products made by the company comply with the U.S.'s NSF quality standard.

Since its establishment, Matthew has increased the use of various kinds of raw materials to facilitate production of multifunctional products. In the early stage, the company adopted only iron wire to produce metal racks. Today it also uses iron plate, iron pipe, aluminum alloy, stainless steel, plastics, glass and wood.

So far the company has acquired many patents in the United States, Japan, United Kingdom, Germany, France, Taiwan, and mainland China.

"We export all of our products, mostly on an OEM basis, " says Yang. "Japan is our largest outlet by taking up 60% of our total sales, followed by Europe with 35% and the U.S. 5%. This market mix underscores the reliability of our quality."

©1995-2006 Copyright China Economic News Service All Rights Reserved.