Taiwan Exhibitors Highlight Niche Products at IFFT

Mar 26, 2004 Ι Industry News Ι Furniture Ι By Philip, CENS

Taiwanese companies targeted niche sectors of the Japanese market in their displays at the recent International Furniture Tokyo (IFFT) 2003, which was held on Nov. 26-30. This marked a divergence from their past strategy of aiming high-quality, own-design products at mainstream markets.

A total of 45 Taiwanese companies manned booths at the fair, a number second among foreign groups only to the mainland Chinese group with 54 booths. The Italians came in third with 44 exhibitors. The overall number of exhibitors at the show, which took place at Tokyo Bight Sight, an international exhibition center in the Daiba district of the city, was 612.

Many of the Taiwanese exhibitors showcased products that incorporated new materials and new functions. One exhibitor, for example, displayed sofas made of synthetic suede for a comfortable feel. Another showed off a massage chair with a seat and back made of resilient polyester cords to enhance the massaging effect and seating comfort.

Other exhibitors aimed at specific Japanese consumer groups. One, for instance, displayed plastic lattices and flower shelves designed to replace similar wooden products now used in the yards of Japanese country houses.

These displays were much different from those featuring mainstream products such as the computer tables, dining tables, and sofas that made up the bulk of Taiwanese exhibits in the past. They reflected the frustration of the island's furniture makers in trying to win acceptance of their self-designed products in mainstream Japanese markets.

This change also announced a fresh effort by Taiwanese manufacturers to maintain their presence in the Japanese market, where they have been suffering a steady decline in recent years. Mainland China overtook Taiwan as the biggest source of imported furniture in Japan in 2002, and last year the island also fell behind Thailand in the first half of the year with a 17% decline to 19.8 billion Japanese yen (US$170 million at 110 yen:US$1). During the same period, mainland China saw its furniture exports to Japan soar by 21%, to 67.7 billion yen (US$615 million).

Many of the products featured in the Taiwan pavilion this year were made by Taiwan-invested factories in Vietnam, where Taiwanese manufacturers started moving three years ago. There are over 400 such factories, located in Binh Duong Province near Ho Chi Minh City. Most of these are integrated plants which, manufacturers say, help them to cut costs and maintain consistent quality'especially since Vietnamese workers earn only around NT$1,000 (US$29) a month, less than half the pay of mainland Chinese workers.

The highlight of the exhibit's Japanese pavilion was the 'Asian Next?section, which featured Japanese-made furniture especially designed to penetrate overseas markets. The 'Asian Next?program was organized by leading Japanese furniture makers with the aim of revitalizing their exports, which have stagnated following the sharp appreciation of the yen.

Highlights of the Taiwan Exhibits

Sage Furniture Co. showcased a sofa upholstered in polyester suede. This material was first used by Italian furniture makers in late 2002, and it was introduced as a sofa covering in Taiwan last year following the local development of its production. The sofa set on display, consisting of three items, is priced at US$300, which is 25-30% lower than the price of similar Italian products but 40% higher than a set upholstered in cotton. The synthetic suede covers can be removed for dry-cleaning. The new products are already on the market in the United States, reports Chen Te-chao, Sage's executive director, and their debut in Japan is expected to help gain entry into the market there.

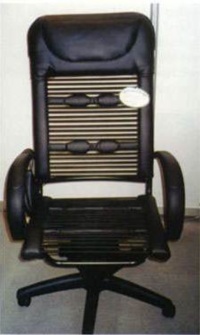

Chia Chi Ya Enterprise Co. displayed a massage chair using polyester cords for its seat and back. Hsiao Yun-chien, the firm's general manager, claimed that his new product has a better massaging effect and is more comfortable than other massage chairs, which pad their seats and backs with foam rubber. If the foam stuffing is thick, he explained, it reduces the massaging effect; if it is thin, it is uncomfortable. His own chair joins the polyester cords to the frame with patented connectors; the patent protects the company's market, since the cords of copycat chairs, which cannot use the unique connectors, will loosen after a few months of use. The motor's fastening device is also patented, and the motor offers five different rhythms and four different levels of force.

The new massage chair, which can accommodate users up to 200 kilograms in weight and comes with a five-year warranty, is a follow-up of Chia Chi Ya's polyester-cord chairs, which are selling in the U.S., Europe (mainly Germany), Japan, and Taiwan at an overall rate of 10,000 units per month.

Another unique kind of chair, featuring a seat and back of U.S.-made mesh and adjustable armrests, was displayed by Comfordy Co. The patented chair, which has passed BIFMA testing in the U.S., has a load capacity of 150 kilos and comes with a two-year warranty. It is tagged at US$140 FOB.

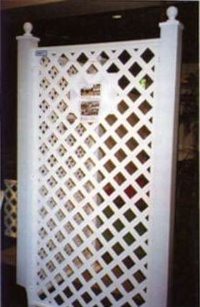

Plastic lattices and flower shelves were the highlights of the booth manned by Taiwan Harlin Enterprises Co. Unlike wooden counterparts, these products are resistant to humidity. They also cost twice as much as wooden items. They come in a choice of three colors and various wood-grain patterns.

The plastic flower shelves use a frame of large plastic tubes and have thick braces for solid construction. They are knock/down products that can be placed in thin packages to cut down on shipping space, and they are easily assembled by simply sliding the parts into place with no need for nails or screws.

The company paid more than NT$200 million (US$5.9 million) for the German equipment and technology (along with molds) used in the production of its plastic lattices and flower shelves. Marketing director Joseph Hsu reported that these products will account for 15% of Taiwan Harlin's 2004 revenue, and are becoming especially important in light of an erosion of profits (due to increasing competition from developing countries) from the firm's mainstay products, plastic outdoor tables and chairs. The company also turns out plastic pallets for warehouses at its factory in Taichung, central Taiwan, which has a work force of 100. Last year, revenues amounted to an estimated NT$300 million (US$8.8 million).

Iron Wood Furniture Co. showcased a coffee table having a hollow medium-density-fiber (MDF) top filled with honeycomb cardboard. The table has ABS castors and is priced at US$30 FOB. The company also displayed a US$90 dining table set; like the coffee table, it was produced at the company's new Vietnam Plan which conducted trial runs last March and has a work force of 100. The plant's integrated operations include sanding and painting, and each of its products is subject to strict quality controls at every step of production. Its workers are trained with the help of engineers from mainland China.

This US$1.5-million factory is the first stage of a three-stage investment project which calls for a total outlay of US$3 million and will eventually cover 5,000 pings (one ping equals 36 square feet) of floorspace, reported marketing manager Asia Lin. The marketing manager said that his company focuses on MDF and bentwood furniture, which is environment-friendly and will never go out of fashion.

Another table, featuring a hollow ash top filled with honeycomb cardboard, was the highlight of the display organized by Taiwan Chuang Dar Industrial Co. The company's general manager, Chang Chin-shan, said that the table can hold a weight of 100 kilos.

First put on the market in 2002, this new table is steadily becoming a mainstay in the company's product line. It is strongly price-competitive, costing only half as much as a solid-wood counterpart. It can also be produced quickly, in contrast to solid-wood furniture, making it good for mass production. The table is selling briskly in Europe, especially in the United Kingdom and Germany, helping to double the firm's exports to that region to US$6 million last year. Sales in the U.S. and Japan amounted to about US$2 million each.

Thanks largely to strong demand in Europe, Chang said at the show, Taiwan Chuang Dar believes that its exports will grow 100% in 2004, to US$20 million. Sales (and profit margins) in Japan have been declining steadily in recent years, but Chang stressed that the company also gains from that market by learning Japanese technology and quality standards. Chang's hopes were that that his efforts at IFFT 2003 would help revitalize his firm's sales in Japan.

GHP International (Vietnam) Co. also displayed products from a new factory in Vietnam. One of its notable products was a coffee table featuring an MDF top coated with lacquer and available with manually embedded shells in various patterns, with strokes of paint added. The table is aimed at Japanese consumers in the medium-to-high end of the market. Similarly surfaced tea-service dishes were also on display.

The US$1 million Vietnamese factory began production in November 2002 and employs 120 workers, and the company plans to invest an additional US$3 million to expand production there, reported the firm's president, Henry Chang.

Long Valley Enterprise Co., a trading firm, displayed wardrobes with plastic blinds instead of the traditional doors. The easy-to-assemble DIY product was first introduced last October and, said company executive Robert Lee, is selling well in Japan at 30,000-50,000 yen (US$270-450) each. The company also showcased a screen made of a newly developed material that looks like the paper used for canvases in traditional Chinese painting. The new material, made of PEVA and other chemicals, can withstand extreme temperatures with no change in texture.

Long Valley usually rolls out six or seven new products every season. Draft designs of the products are first sent to Japanese customers for comment, and are then modified accordingly prior to mass production. Seventy percent of the company's annual revenues (US$4 million) come from the Japanese market, mainly via mail-order houses.

Self-designed chairs priced under US$10 FOB each were the highlight of the booth manned by Como Furniture Enterprises Co. In addition to a graceful design, the chairs boast a solid structure as attested by BIFMA approval. They are the first result of the firm's plan to develop a collection of chairs totaling eight models by the end of the first quarter of 2004. Production is handled at a 100-worker plant in the Changhua Coastal Industrial Zone in central Taiwan; the plant, which now has a capacity of 40,000 chairs a month, will be further expanded.

The chairs on display marked a fresh effort by the firm to penetrate the Japanese market, following its failure with self-designed computer desks during the two previous IFFT shows.

With an eye on the huge market comprised by Japan's aged population, Jann Yei showcased two models of its electronic sickbed. The first model has three motors to adjust height and raise both the head and the foot of the bed, and is priced at US$450; the other has two motors for adjusting height and raising the head of the bed, and carries a US$340 tag. Both models are equipped with foldable tables. The company developed its sick beds in 2002 and has been improving them ever since; despite a lack of firm orders from Japanese buyers, Chen Ton-yi, Jann Yei's managing director, is sure his marketing efforts there will bear fruit this year.

The A&J Co. has also been disappointed in its marketing efforts in Japan, but returned to IFFT in 2003 with a collection of glass coffee tables featuring curving iron-tube stands coated with elastic mesh, evidencing a kind of minimalist grace. The mesh can be removed for cleaning, and can be replaced with mesh of different colors.

The company's displays of computer desks with wooden tops at the previous two IFFT shows failed to impress Japanese buyers. General Manager Jeneson Hsu insisted, however, that A&J will continue promoting its self-designed products in the future in the hope of winning OEM (original equipment manufacturer) orders from Japan. That country now accounts for 80% of the company's US$3.5 million in furniture exports, with sales mainly through Sogo Gaisha.

Perhaps the most eye-catching of the Taiwanese booths at IFFT 2003 was that occupied by the Restonic Group. The manning of this large booth at a premium site on the showgrounds corresponded with the completion of a US$12 million expansion project at the company's 1,000-worker factory in Dongguan, China. This facility, which also employs Italian and Japanese technicians, elevates Restonic from a regional agent for the production and sale of mattresses for Restonic of the U.S. and Musterring of Germany to the status of a producer of a wide range of furniture products including bed mattresses, sofas, and dining tables. A second-stage expansion at the plant is to be completed in May 2004.

A total of 45 Taiwanese companies manned booths at the fair, a number second among foreign groups only to the mainland Chinese group with 54 booths. The Italians came in third with 44 exhibitors. The overall number of exhibitors at the show, which took place at Tokyo Bight Sight, an international exhibition center in the Daiba district of the city, was 612.

Many of the Taiwanese exhibitors showcased products that incorporated new materials and new functions. One exhibitor, for example, displayed sofas made of synthetic suede for a comfortable feel. Another showed off a massage chair with a seat and back made of resilient polyester cords to enhance the massaging effect and seating comfort.

Other exhibitors aimed at specific Japanese consumer groups. One, for instance, displayed plastic lattices and flower shelves designed to replace similar wooden products now used in the yards of Japanese country houses.

These displays were much different from those featuring mainstream products such as the computer tables, dining tables, and sofas that made up the bulk of Taiwanese exhibits in the past. They reflected the frustration of the island's furniture makers in trying to win acceptance of their self-designed products in mainstream Japanese markets.

This change also announced a fresh effort by Taiwanese manufacturers to maintain their presence in the Japanese market, where they have been suffering a steady decline in recent years. Mainland China overtook Taiwan as the biggest source of imported furniture in Japan in 2002, and last year the island also fell behind Thailand in the first half of the year with a 17% decline to 19.8 billion Japanese yen (US$170 million at 110 yen:US$1). During the same period, mainland China saw its furniture exports to Japan soar by 21%, to 67.7 billion yen (US$615 million).

Many of the products featured in the Taiwan pavilion this year were made by Taiwan-invested factories in Vietnam, where Taiwanese manufacturers started moving three years ago. There are over 400 such factories, located in Binh Duong Province near Ho Chi Minh City. Most of these are integrated plants which, manufacturers say, help them to cut costs and maintain consistent quality'especially since Vietnamese workers earn only around NT$1,000 (US$29) a month, less than half the pay of mainland Chinese workers.

The highlight of the exhibit's Japanese pavilion was the 'Asian Next?section, which featured Japanese-made furniture especially designed to penetrate overseas markets. The 'Asian Next?program was organized by leading Japanese furniture makers with the aim of revitalizing their exports, which have stagnated following the sharp appreciation of the yen.

Highlights of the Taiwan Exhibits

Sage Furniture Co. showcased a sofa upholstered in polyester suede. This material was first used by Italian furniture makers in late 2002, and it was introduced as a sofa covering in Taiwan last year following the local development of its production. The sofa set on display, consisting of three items, is priced at US$300, which is 25-30% lower than the price of similar Italian products but 40% higher than a set upholstered in cotton. The synthetic suede covers can be removed for dry-cleaning. The new products are already on the market in the United States, reports Chen Te-chao, Sage's executive director, and their debut in Japan is expected to help gain entry into the market there.

Chia Chi Ya Enterprise Co. displayed a massage chair using polyester cords for its seat and back. Hsiao Yun-chien, the firm's general manager, claimed that his new product has a better massaging effect and is more comfortable than other massage chairs, which pad their seats and backs with foam rubber. If the foam stuffing is thick, he explained, it reduces the massaging effect; if it is thin, it is uncomfortable. His own chair joins the polyester cords to the frame with patented connectors; the patent protects the company's market, since the cords of copycat chairs, which cannot use the unique connectors, will loosen after a few months of use. The motor's fastening device is also patented, and the motor offers five different rhythms and four different levels of force.

The new massage chair, which can accommodate users up to 200 kilograms in weight and comes with a five-year warranty, is a follow-up of Chia Chi Ya's polyester-cord chairs, which are selling in the U.S., Europe (mainly Germany), Japan, and Taiwan at an overall rate of 10,000 units per month.

Another unique kind of chair, featuring a seat and back of U.S.-made mesh and adjustable armrests, was displayed by Comfordy Co. The patented chair, which has passed BIFMA testing in the U.S., has a load capacity of 150 kilos and comes with a two-year warranty. It is tagged at US$140 FOB.

Plastic lattices and flower shelves were the highlights of the booth manned by Taiwan Harlin Enterprises Co. Unlike wooden counterparts, these products are resistant to humidity. They also cost twice as much as wooden items. They come in a choice of three colors and various wood-grain patterns.

The plastic flower shelves use a frame of large plastic tubes and have thick braces for solid construction. They are knock/down products that can be placed in thin packages to cut down on shipping space, and they are easily assembled by simply sliding the parts into place with no need for nails or screws.

The company paid more than NT$200 million (US$5.9 million) for the German equipment and technology (along with molds) used in the production of its plastic lattices and flower shelves. Marketing director Joseph Hsu reported that these products will account for 15% of Taiwan Harlin's 2004 revenue, and are becoming especially important in light of an erosion of profits (due to increasing competition from developing countries) from the firm's mainstay products, plastic outdoor tables and chairs. The company also turns out plastic pallets for warehouses at its factory in Taichung, central Taiwan, which has a work force of 100. Last year, revenues amounted to an estimated NT$300 million (US$8.8 million).

Iron Wood Furniture Co. showcased a coffee table having a hollow medium-density-fiber (MDF) top filled with honeycomb cardboard. The table has ABS castors and is priced at US$30 FOB. The company also displayed a US$90 dining table set; like the coffee table, it was produced at the company's new Vietnam Plan which conducted trial runs last March and has a work force of 100. The plant's integrated operations include sanding and painting, and each of its products is subject to strict quality controls at every step of production. Its workers are trained with the help of engineers from mainland China.

This US$1.5-million factory is the first stage of a three-stage investment project which calls for a total outlay of US$3 million and will eventually cover 5,000 pings (one ping equals 36 square feet) of floorspace, reported marketing manager Asia Lin. The marketing manager said that his company focuses on MDF and bentwood furniture, which is environment-friendly and will never go out of fashion.

Another table, featuring a hollow ash top filled with honeycomb cardboard, was the highlight of the display organized by Taiwan Chuang Dar Industrial Co. The company's general manager, Chang Chin-shan, said that the table can hold a weight of 100 kilos.

First put on the market in 2002, this new table is steadily becoming a mainstay in the company's product line. It is strongly price-competitive, costing only half as much as a solid-wood counterpart. It can also be produced quickly, in contrast to solid-wood furniture, making it good for mass production. The table is selling briskly in Europe, especially in the United Kingdom and Germany, helping to double the firm's exports to that region to US$6 million last year. Sales in the U.S. and Japan amounted to about US$2 million each.

Thanks largely to strong demand in Europe, Chang said at the show, Taiwan Chuang Dar believes that its exports will grow 100% in 2004, to US$20 million. Sales (and profit margins) in Japan have been declining steadily in recent years, but Chang stressed that the company also gains from that market by learning Japanese technology and quality standards. Chang's hopes were that that his efforts at IFFT 2003 would help revitalize his firm's sales in Japan.

GHP International (Vietnam) Co. also displayed products from a new factory in Vietnam. One of its notable products was a coffee table featuring an MDF top coated with lacquer and available with manually embedded shells in various patterns, with strokes of paint added. The table is aimed at Japanese consumers in the medium-to-high end of the market. Similarly surfaced tea-service dishes were also on display.

The US$1 million Vietnamese factory began production in November 2002 and employs 120 workers, and the company plans to invest an additional US$3 million to expand production there, reported the firm's president, Henry Chang.

Long Valley Enterprise Co., a trading firm, displayed wardrobes with plastic blinds instead of the traditional doors. The easy-to-assemble DIY product was first introduced last October and, said company executive Robert Lee, is selling well in Japan at 30,000-50,000 yen (US$270-450) each. The company also showcased a screen made of a newly developed material that looks like the paper used for canvases in traditional Chinese painting. The new material, made of PEVA and other chemicals, can withstand extreme temperatures with no change in texture.

Long Valley usually rolls out six or seven new products every season. Draft designs of the products are first sent to Japanese customers for comment, and are then modified accordingly prior to mass production. Seventy percent of the company's annual revenues (US$4 million) come from the Japanese market, mainly via mail-order houses.

Self-designed chairs priced under US$10 FOB each were the highlight of the booth manned by Como Furniture Enterprises Co. In addition to a graceful design, the chairs boast a solid structure as attested by BIFMA approval. They are the first result of the firm's plan to develop a collection of chairs totaling eight models by the end of the first quarter of 2004. Production is handled at a 100-worker plant in the Changhua Coastal Industrial Zone in central Taiwan; the plant, which now has a capacity of 40,000 chairs a month, will be further expanded.

The chairs on display marked a fresh effort by the firm to penetrate the Japanese market, following its failure with self-designed computer desks during the two previous IFFT shows.

With an eye on the huge market comprised by Japan's aged population, Jann Yei showcased two models of its electronic sickbed. The first model has three motors to adjust height and raise both the head and the foot of the bed, and is priced at US$450; the other has two motors for adjusting height and raising the head of the bed, and carries a US$340 tag. Both models are equipped with foldable tables. The company developed its sick beds in 2002 and has been improving them ever since; despite a lack of firm orders from Japanese buyers, Chen Ton-yi, Jann Yei's managing director, is sure his marketing efforts there will bear fruit this year.

The A&J Co. has also been disappointed in its marketing efforts in Japan, but returned to IFFT in 2003 with a collection of glass coffee tables featuring curving iron-tube stands coated with elastic mesh, evidencing a kind of minimalist grace. The mesh can be removed for cleaning, and can be replaced with mesh of different colors.

The company's displays of computer desks with wooden tops at the previous two IFFT shows failed to impress Japanese buyers. General Manager Jeneson Hsu insisted, however, that A&J will continue promoting its self-designed products in the future in the hope of winning OEM (original equipment manufacturer) orders from Japan. That country now accounts for 80% of the company's US$3.5 million in furniture exports, with sales mainly through Sogo Gaisha.

Perhaps the most eye-catching of the Taiwanese booths at IFFT 2003 was that occupied by the Restonic Group. The manning of this large booth at a premium site on the showgrounds corresponded with the completion of a US$12 million expansion project at the company's 1,000-worker factory in Dongguan, China. This facility, which also employs Italian and Japanese technicians, elevates Restonic from a regional agent for the production and sale of mattresses for Restonic of the U.S. and Musterring of Germany to the status of a producer of a wide range of furniture products including bed mattresses, sofas, and dining tables. A second-stage expansion at the plant is to be completed in May 2004.

©1995-2006 Copyright China Economic News Service All Rights Reserved.