×

【Wire Shelving】Whole plant Equipment

Introduction of wire rack and mesh production equipment and production line machine.

| Process |

Workpiece |

Type |

Model |

Machine Introduction |

| Straight Line |

|

Straightening Machine |

SJS-103

SJS-105

|

|

| Zig zag Line |

|

Zig zag wire forming machine |

SW-PH60 |

|

|

Welding

(Straight line + Zig zag line)

|

|

Pneumatic spot Welding Machine

Pneumatic double-head spot Welding Machine

Pneumatic four-head spot Welding Machine

Multi-Point Spot Welding Machine

|

SA-600

SA-1200T2

SA-1200T4

SA-1500WD

|

|

|

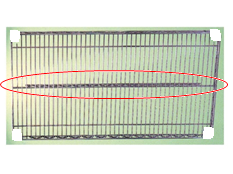

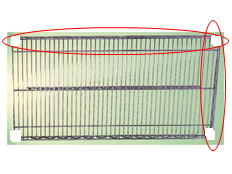

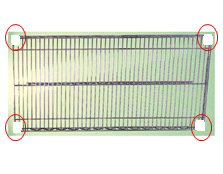

Mesh welding

(Straight Line + Straight Line)

|

|

Multi-Point Spot Welding Machine

Dual-layer Multi-point Spot Welding Machine

Multi-Jig Mesh Welding Machine

Wire Mesh Welding Machine

Wire Mesh Welding Machine

|

SA-1500DD

SA-1500AF

SA-1500DL-1

GSA-80L/1200

|

|

| Spit Trimming |

|

Spit Trimming Machine

Oil-Pressure Line Cutting Machine

|

CEA-102

SZD-C400

|

|

|

Welding

(Straight line + Zig zag line)

|

|

Multi-Point Spot Welding Machine |

SA-1500WD |

|

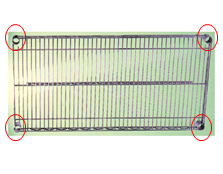

Welding

(Mesh + Right angle Line)

|

|

L-type multi-Point Spot Welding Machine |

SA-1500LD-W |

|

|

Shearing

(Four corners of mesh)

|

|

Hydraulic angle cutting machine |

SZD-SOC-200 |

|

|

Welding

(Four corner of mesh + tube)

|

|

MIG Welding Stand

|

SR-400RC

CO2-250

|

|

【Bi-Metal Screw】Butt Welder

【3D WIRE MESH FENCES】 WELDING MACHINES

【Razor Mesh】Welding Machine

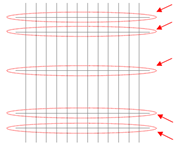

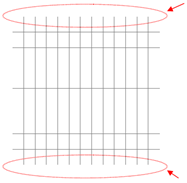

【Truss Construction / Lattice Girder】Whole plant Equipment

- ire feeder: 5 sets, width:2100m/m, the max load: 2 tons, adopting air-pressure brake.

- Straightening system: Composed of 5 sets straightening device, and applicable diameter is 6-20m/m.

- Storing system: storing the pre-straightened wire.

- Zigzag forming system: Adjusting the Zigzag height by motor which save laborers and easy adjusting.

- Welding System: Equipped with 2 sets of 200KVA transformers and our own developed controller to be in the process of welding.

- Pushing and cutting system: Operated by Oil-pressure system, 30nt/in max output, steady and quick.

- The above is process 1 which suits for railroad tie, rigid frame of plant roof, floor, and so on.

- Holding System: Holding the finished workpiece to the terminal. It can be easily to be integrated with other working process.

- Bottom Plate System: leveling the bundle of bottom plate, and cutting to the set length.

- Multi-point Spot Welding: Weld 5 sets of zigzag truss with bottom plate.

The bottom plate structure, applying to shell structure, floor, successive wall, replaces the traditional type and shortens work time.

【Mesh Repairing Purpose】Portable Spot Welder

【Bird Spikes】Auto Welding Machine

- Quick and Easy to weld the stainless steel base plate (hole& mark on) with wires to bird spikes and automatically flatten & cut the spike sets into pieces.

- Automatically press (bend) the spikes into form(s) with settle module right after shift out from the welding machine.

- Stack the finalized bird spikes ready for post procedures.

- Auto line plate and cross wire flatten/straighten & feeding.

- PLC control system for ease and easy operation.

【Pipe Oil Mesh】Welding Machine

【Spacers mesh】welding mahine